Oil well casing is a crucial component in the drilling and production of oil and gas. It provides structural integrity to the wellbore, preventing it from collapsing and ensuring the safety of drilling operations.

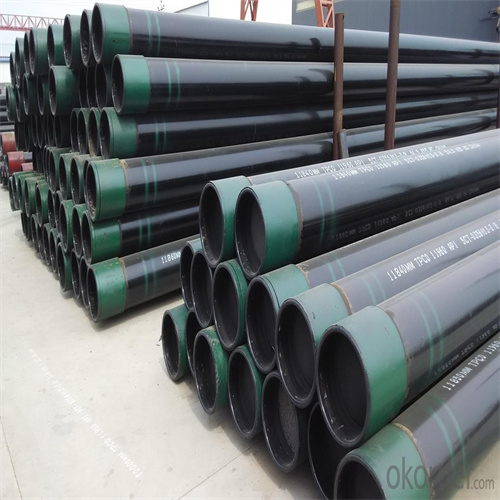

The casing is placed inside the drilled hole and acts as a barrier between the formation and the drilling fluids. Made of high-strength materials, such as steel, it withstands the forces and pressures encountered during drilling.

Casing an oil well involves selecting the appropriate size and grade of casing based on factors like the depth of the well, formation characteristics, and anticipated pressure levels. Different types of casing, such as surface casing, intermediate casing, and production casing, are used at different stages of the drilling process.

API 5CT casing, specifically, follows strict standards set by the American Petroleum Institute (API). These standards ensure that the casing meets specific requirements for strength, corrosion resistance, and other performance characteristics.

In addition to protecting the well, casing also facilitates the efficient extraction of oil and gas. It allows for the installation of downhole tools and equipment, as well as the control of fluid flow within the well.

Proper selection, installation, and maintenance of oil well casing are essential for successful oil and gas production. By choosing the right casing and following industry best practices, drillers can ensure the integrity and longevity of the well.

When it comes to drilling equipment, R2/R3/API 5b Oil Drilling Equipment is commonly used. This equipment includes rigs, drill bits, and other tools designed to handle the challenges of oil drilling operations.

In conclusion, casing plays a vital role in oil well drilling, providing protection, structural support, and enabling efficient oil and gas recovery. Understanding the importance of oil well casing is crucial for ensuring the safety and productivity of oil and gas fields.