The process of Manufacturing steel casing Pipe in china

Steel casing pipe is an essential component in various industries, including Oil and gas, construction, and water well drilling. In China, the manufacturing process of steel casing pipe is a meticulous and precise operation that requires advanced technology and skilled labor. From the selection of raw materials to the final inspection of the finished product, every step in the manufacturing process plays a crucial role in ensuring the quality and durability of the steel casing pipe.

Auto Engine Oil Pump Screen Assemblies Pipe Tube Factory

The first step in manufacturing steel casing pipe is the selection of high-quality raw materials. In China, manufacturers typically use carbon steel or stainless steel as the base material for casing pipe production. These materials are chosen for their strength, durability, and resistance to corrosion. The raw materials are carefully inspected and tested to ensure they meet the required specifications before being processed further.

Once the raw materials have been selected, they are cut into the desired lengths and shapes using cutting-edge machinery. The cutting process is crucial in ensuring the accuracy and precision of the steel casing pipe. After the initial cutting, the raw materials are then heated to a specific temperature in a furnace to make them more malleable for further processing.

Once the raw materials have been selected, they are cut into the desired lengths and shapes using cutting-edge machinery. The cutting process is crucial in ensuring the accuracy and precision of the steel casing pipe. After the initial cutting, the raw materials are then heated to a specific temperature in a furnace to make them more malleable for further processing.

The next step in the manufacturing process is forming the steel casing pipe. This is done by passing the heated raw materials through a series of rollers and molds that shape them into the desired size and thickness. The forming process requires a high level of precision and expertise to ensure that the casing pipe meets the required specifications.

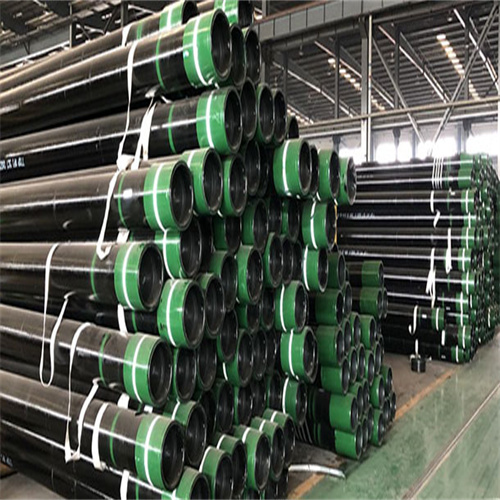

After the steel casing pipe has been formed, it undergoes a series of finishing processes to enhance its durability and appearance. These processes may include heat treatment, surface coating, and threading. Heat treatment is used to improve the strength and hardness of the casing pipe, while surface coating helps protect it from corrosion and rust. Threading is essential for connecting the casing pipe to other components in various applications.

Once the finishing processes are complete, the steel casing pipe undergoes a rigorous inspection to ensure it meets the required quality standards. In China, manufacturers use advanced testing equipment and techniques to check the dimensions, strength, and integrity of the casing pipe. Any defects or imperfections are identified and corrected before the product is approved for shipment.

In conclusion, the manufacturing process of steel casing pipe in China is a complex and intricate operation that requires precision, expertise, and advanced technology. From the selection of raw materials to the final inspection of the finished product, every step in the process is crucial in ensuring the quality and durability of the casing pipe. By following strict quality control measures and employing skilled labor, chinese manufacturers are able to produce high-quality steel casing pipe that meets the demands of various industries around the world.

oil drum cover