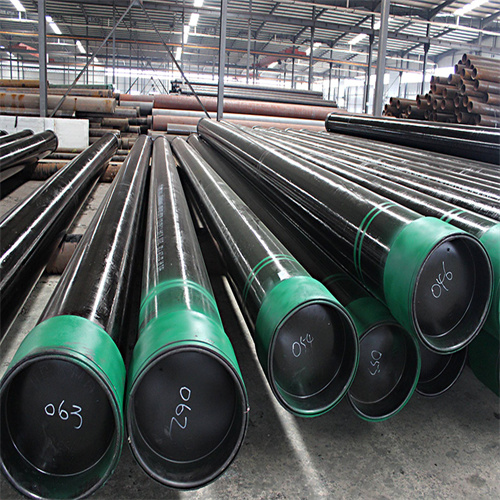

Exploring the Benefits of chinese high-quality Oil Pipe production processes

The Chinese oil pipe production process is renowned for its high-quality standards and efficiency. This production process has been developed over many years and is now considered one of the most reliable and cost-effective methods of producing oil pipes. In this article, we will explore the benefits of the Chinese oil pipe production process and how it can help businesses save money and time.

One of the main advantages of the Chinese oil pipe production process is its cost-effectiveness. The process is designed to be as efficient as possible, meaning that businesses can save money on materials and labor costs. Additionally, the process is designed to be highly automated, meaning that businesses can reduce their labor costs even further. This cost-effectiveness makes the Chinese oil pipe production process an attractive option for businesses looking to reduce their production costs.

Another benefit of the Chinese oil pipe production process is its reliability. The process is designed to produce high-quality pipes that are resistant to corrosion and other environmental factors. This ensures that businesses can rely on the pipes produced by the process to last for many years. Additionally, the process is designed to be highly efficient, meaning that businesses can produce large quantities of pipes in a short amount of time. This makes the Chinese oil pipe production process an ideal choice for businesses looking to increase their production capacity.

Finally, the Chinese oil pipe production process is designed to be environmentally friendly. The process uses fewer resources than traditional methods, meaning that businesses can reduce their carbon footprint. Additionally, the process produces fewer emissions, meaning that businesses can reduce their environmental impact even further. This makes the Chinese oil pipe production process an attractive option for businesses looking to reduce their environmental impact.

In conclusion, the Chinese oil pipe production process is an efficient and cost-effective method of producing high-quality pipes. The process is designed to be highly automated, meaning that businesses can reduce their labor costs and increase their production capacity. Additionally, the process is designed to be reliable and environmentally friendly, meaning that businesses can reduce their environmental impact and save money in the long run. For these reasons, the Chinese oil pipe production process is an attractive option for businesses looking to reduce their production costs and increase their production capacity.

Examining the Latest innovations in Chinese High-Quality Oil Pipe Production Technologies

The Chinese oil pipe industry has seen a surge in technological advancements in recent years, with the introduction of new production technologies that have enabled the production of high-quality oil pipes. This article will examine the latest innovations in Chinese high-quality oil pipe production technologies, and discuss their potential implications for the industry.

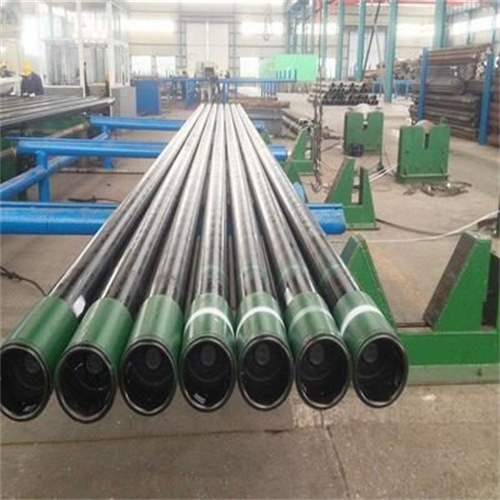

One of the most significant developments in Chinese oil pipe production technologies is the introduction of automated production lines. Automated production lines are capable of producing oil pipes with greater precision and accuracy than traditional manual production methods. This has enabled Chinese manufacturers to produce oil pipes with higher levels of quality and consistency. Additionally, automated production lines are more efficient than manual production methods, allowing manufacturers to produce oil pipes at a faster rate.

Another major innovation in Chinese oil pipe production technologies is the use of advanced materials. Chinese manufacturers are now using advanced materials such as stainless steel, carbon steel, and alloy steel to produce oil pipes. These materials are more durable and resistant to corrosion than traditional materials, allowing manufacturers to produce oil pipes with greater longevity. Additionally, advanced materials are more cost-effective than traditional materials, allowing manufacturers to produce oil pipes at a lower cost.

Finally, Chinese manufacturers are now utilizing advanced manufacturing techniques such as 3D printing and laser cutting to produce oil pipes. 3D printing allows manufacturers to produce oil pipes with complex shapes and intricate details, while laser cutting enables manufacturers to produce oil pipes with precise dimensions and tolerances. These advanced manufacturing techniques allow manufacturers to produce oil pipes with greater accuracy and consistency than traditional methods.

The introduction of these new production technologies has enabled Chinese manufacturers to produce high-quality oil pipes with greater efficiency and cost-effectiveness. This has allowed Chinese manufacturers to remain competitive in the global oil pipe market, and has enabled them to provide customers with superior products. As these technologies continue to evolve, it is likely that Chinese manufacturers will continue to lead the way in the production of high-quality oil pipes.