Maximizing Oil Well Performance: The Role of high Performance casing

High Performance Oil Well Casing: Maximizing Oil Well Performance

In the intricate web of processes involved in oil drilling, every component plays a crucial role in ensuring optimal performance. Among these components, oil well casing stands out as a fundamental element that directly impacts the efficiency and longevity of oil wells. High performance oil well casing, in particular, holds immense significance in maximizing oil well performance, offering a range of benefits that contribute to enhanced productivity and cost-effectiveness.

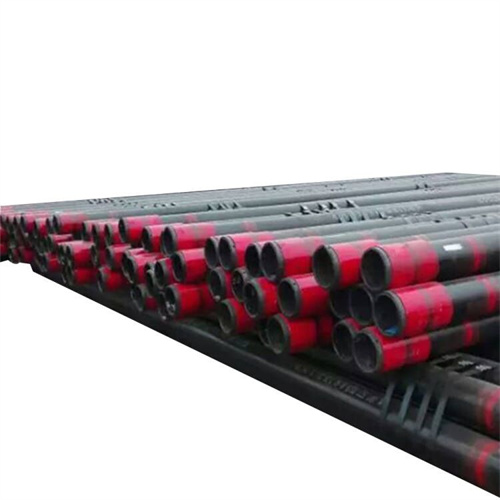

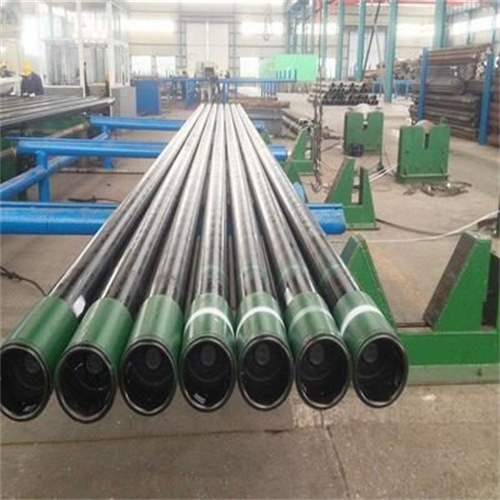

At the core of its importance lies the role of high performance oil well casing in providing structural integrity and stability to the wellbore. Unlike conventional casing materials, high performance casing is engineered to withstand extreme conditions, including high pressures, corrosive environments, and mechanical stresses. This superior durability not only extends the lifespan of the casing but also enhances the overall reliability of the well, minimizing the risk of costly failures and downtime.

Moreover, high performance oil well casing offers unparalleled resistance to corrosion, a common challenge in oil drilling operations. By utilizing advanced materials and coatings, such as corrosion-resistant alloys and polymer liners, high performance casing mitigates the detrimental effects of corrosive substances present in the well fluid, thereby preserving the integrity of the casing and preventing leakage or contamination of the surrounding environment.

In addition to its mechanical and chemical resilience, high performance oil well casing facilitates improved wellbore stability and fluid management. Its superior strength and tight tolerances ensure optimal wellbore geometry, reducing the likelihood of deviations or collapses during drilling and completion processes. Furthermore, advanced casing designs, such as premium threaded connections and centralized casing hangers, facilitate efficient fluid flow and cement placement, enhancing well performance and production rates.

API Oil Well Wellhead Equipment Casing Hanger and Tubing Hanger ManufacturerFurthermore, high performance oil well casing plays a pivotal role in reservoir management and environmental stewardship. By creating a barrier between the wellbore and the surrounding formations, casing prevents the migration of fluids and gases, thereby minimizing the risk of reservoir contamination and uncontrolled releases. This containment capability is especially critical in environmentally sensitive areas and during the production of unconventional resources, where stringent regulatory requirements mandate strict adherence to environmental standards.

Beyond its technical capabilities, high performance oil well casing offers significant economic advantages to operators. While the initial investment in premium casing may be higher compared to conventional alternatives, the long-term benefits in terms of reduced maintenance costs, extended well life, and enhanced production far outweigh the upfront expenses. Moreover, the reliability and performance improvements associated with high performance casing contribute to overall operational efficiency and profitability, ensuring a favorable return on investment over the lifecycle of the well.

In conclusion, high performance oil well casing plays a pivotal role in maximizing oil well performance across various dimensions. From enhancing structural integrity and corrosion resistance to improving fluid management and environmental compliance, high performance casing offers a myriad of benefits that are indispensable in today’s demanding oil drilling industry. By investing in advanced materials and technologies, operators can optimize well performance, minimize risks, and achieve sustainable growth in their operations.

oil and gas Pipe insulation job description