Exploring the Different Types of Oil casing and Their Benefits

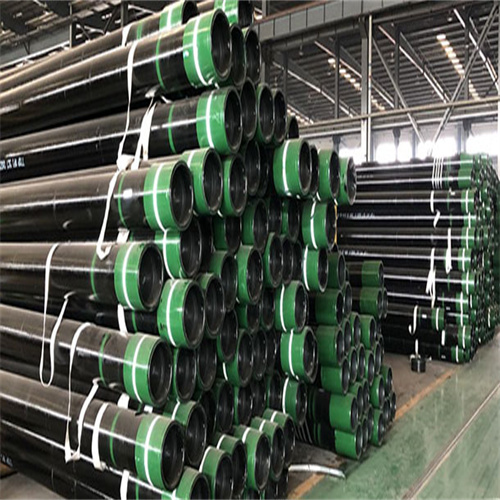

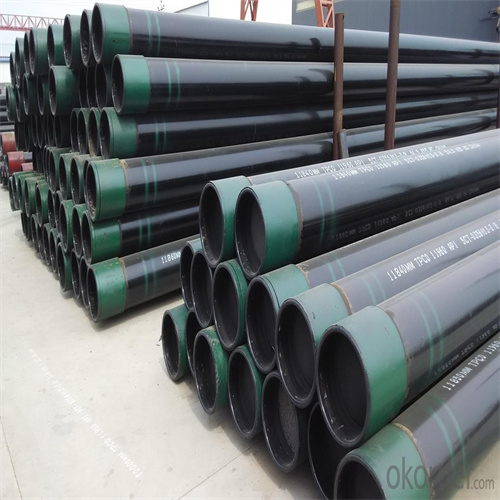

Oil casing is an essential component of any oil well. It is a steel Pipe that is used to line the walls of the well, providing structural integrity and preventing the well from collapsing. It also helps to keep the oil and gas contained within the well, allowing it to be extracted safely and efficiently.

There are several different types of oil casing available, each with its own unique benefits. The most common type is the API casing, which is made from steel and is designed to withstand the high pressures and temperatures found in oil wells. This type of casing is also highly resistant to corrosion, making it a great choice for long-term use.

Another type of oil casing is the premium casing. This type of casing is made from a higher grade of steel and is designed to provide superior strength and durability. It is also more resistant to corrosion and is often used in deeper wells.

The third type of oil casing is the expandable casing. This type of casing is designed to expand as the well is drilled, allowing for a larger diameter and greater pressure containment. This type of casing is often used in deeper wells and is more expensive than the other types of casing.

Finally, there is the liner casing. This type of casing is designed to provide a barrier between the well and the surrounding environment. It is often used in shallow wells and is designed to prevent contamination from entering the well.

No matter which type of oil casing you choose, it is important to ensure that it is properly installed and maintained. This will help to ensure that the well is safe and efficient, and that the oil and gas contained within it can be extracted safely and efficiently.

Analyzing the Impact of model differentiation on Oil Casing Performance

The performance of oil casing is a critical factor in the success of any oil and gas operation. As such, it is important to understand the impact of model differentiation on oil casing performance. Model differentiation refers to the Differences in design, materials, and construction of oil casing models.

When it comes to oil casing performance, model differentiation can have a significant impact. Different models of oil casing can have different levels of strength, durability, and corrosion resistance. This can affect the overall performance of the casing, as well as the safety of the operation.

For example, a model of oil casing with a higher level of strength and durability may be able to withstand higher pressures and temperatures than a model with a lower level of strength and durability. This can be beneficial in operations that require higher pressures and temperatures, as it can help to ensure the safety of the operation.

In addition, different models of oil casing can have different levels of corrosion resistance. This can be important in operations that involve corrosive materials, as it can help to ensure that the casing does not corrode and fail prematurely.

Finally, different models of oil casing can have different levels of flexibility. This can be beneficial in operations that involve tight spaces, as it can help to ensure that the casing can be installed in the desired location.

190.78

Overall, model differentiation can have a significant impact on oil casing performance. It is important to understand the differences between models and select the one that is best suited for the specific operation. Doing so can help to ensure the safety and success of the operation.