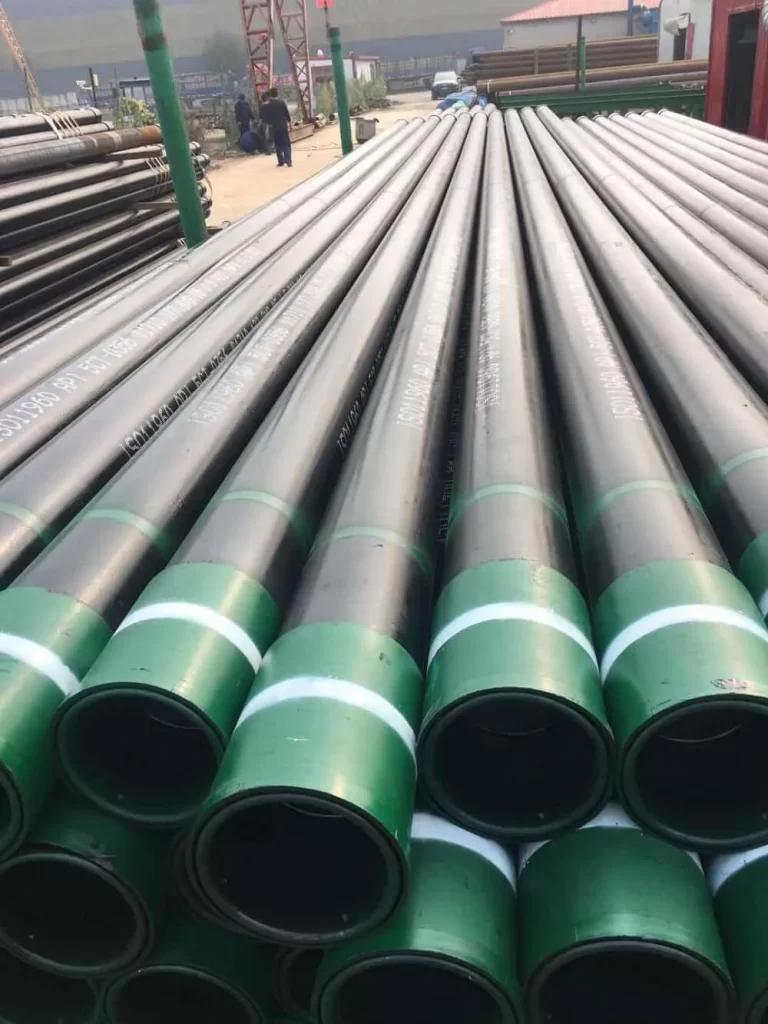

Oil casing: The Backbone of Oil Extraction

Oil casing plays a vital role in the oil extraction process. It is a protective barrier for oil wells and ensures smooth and efficient extraction of oil and gas. This vital component is designed to withstand high pressures, corrosive environments and extreme temperatures, making it a mainstay in the petroleum industry.

The main function of oil casing is to prevent wellbore collapse and to isolate oil and gas reservoirs from surrounding rock formations and fluids. By providing structural support and maintaining well integrity, oil casing enables the safe and efficient extraction of hydrocarbons from deep within the earth’s surface.

In addition, oil casing also serves as a Pipeline for transporting oil and natural gas to the surface, playing a key role in the entire production process. Its durability and elastic properties ensure that extracted resources can be efficiently brought to the surface for further processing and distribution.

In addition to its structural significance, oil casing also helps protect the surrounding environment. By confining oil and gas within the wellbore and preventing any potential leaks or seeps, it helps reduce the risk of environmental contamination and protects ecosystems and communities near where oil is extracted.

The importance of oil casing in oil extraction cannot be overstated. As energy demand continues to grow, the role of oil casing in facilitating the extraction and production of oil and natural gas has become increasingly important. Its reliability, durability and ability to withstand harsh operating conditions make it an indispensable component in the petroleum industry.

In short, oil casing is the cornerstone of oil extraction, ensuring the safety, efficiency and environmental responsibility of oil and gas extraction. Its critical role in maintaining well integrity, facilitating resource transport and protecting the environment underscores its status as an indispensable asset for the petroleum industry.