An Overview of the production process of Oil Pipes: From Raw Materials to Finished Products

The production process of oil pipes starts with the selection of raw materials. The raw materials used for oil pipes are usually steel, aluminum, and other metals. After the raw materials are selected, they are cut into the desired shape and size. Then, the pieces are welded together to form the pipe.

Next, the pipe is tested for strength and durability. This is done by subjecting the pipe to various tests such as pressure tests, corrosion tests, and other tests. Once the pipe passes these tests, it is ready for the next step in the production process.

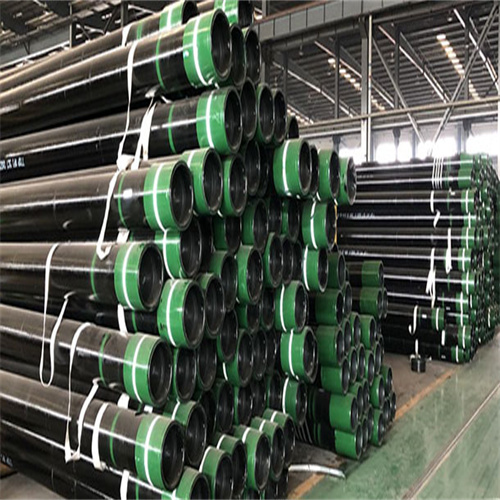

The next step is to coat the pipe with a protective coating. This coating helps to protect the pipe from corrosion and other environmental factors. After the coating is applied, the pipe is ready for the next step in the production process.

The next step is to thread the pipe. This is done by using a machine to cut threads into the pipe. This helps to ensure that the pipe is securely connected to other pipes and components. After the threading is complete, the pipe is ready for the next step in the production process.

The final step in the production process is to inspect the pipe. This is done to make sure that the pipe meets all of the required specifications. Once the inspection is complete, the pipe is ready to be shipped to its destination.

The production process of oil pipes is a complex process that requires a lot of attention to detail. From selecting the right raw materials to inspecting the finished product, each step in the process is important to ensure that the pipe is of the highest quality.