Factors Affecting Customized casing Pipe price

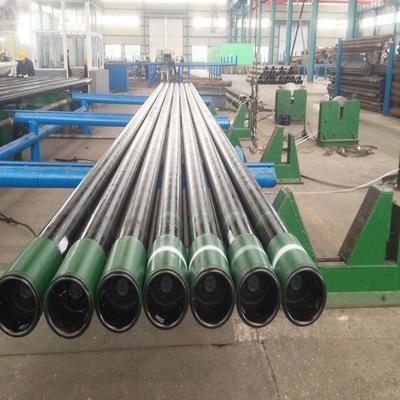

Customized casing pipes are an essential component in various industries, including Oil and gas, construction, and water well drilling. These pipes are designed to protect and support the wellbore, ensuring the integrity of the well and preventing collapse. When it comes to purchasing customized casing pipes, one of the key factors to consider is the price. The price of customized casing pipes can vary significantly depending on a variety of factors. In this article, we will explore some of the key factors that can affect the price of customized casing pipes.

One of the primary factors that can impact the price of customized casing pipes is the material used in their construction. Casing pipes are typically made from a variety of materials, including steel, PVC, and fiberglass. Each material has its own unique properties and benefits, which can affect the overall cost of the casing pipe. Steel casing pipes, for example, are known for their strength and durability, but they tend to be more expensive than PVC or fiberglass pipes. The material used in the construction of the casing pipe will ultimately determine its price.

Another factor that can influence the price of customized casing pipes is the size and length of the pipe. Casing pipes come in a variety of sizes and lengths, and the larger and longer the pipe, the more expensive it is likely to be. The size and length of the casing pipe will depend on the specific requirements of the well or project for which it is being used. Larger and longer casing pipes require more material and labor to manufacture, which can drive up the price.

The customization of casing pipes can also impact their price. Customized casing pipes are designed to meet the specific needs and requirements of a particular project, which can involve additional design and manufacturing costs. Customization can include features such as special coatings, threading, or connections, which can add to the overall price of the casing pipe. The level of customization required will depend on the unique specifications of the project, and this will ultimately affect the price of the casing pipe.

running heating oil pipe undergroundIn addition to material, size, length, and customization, other factors can also influence the price of customized casing pipes. These factors include market demand, production costs, and overhead expenses. Market demand can affect the price of casing pipes, as high demand can drive up prices due to limited supply. Production costs, such as labor, equipment, and raw materials, can also impact the price of casing pipes. Overhead expenses, such as transportation and storage, can add to the overall cost of the casing pipe.

API Downhole ToolsIn conclusion, the price of customized casing pipes can vary depending on a variety of factors, including the material used, size, length, customization, market demand, production costs, and overhead expenses. When purchasing customized casing pipes, it is important to consider these factors and their impact on the price. By understanding the factors that can affect the price of customized casing pipes, buyers can make informed decisions and ensure that they are getting the best value for their investment.

Tips for Finding Affordable Customized Casing Pipe Options

When it comes to finding affordable customized casing pipe options, there are a few key factors to consider. Customized casing pipes are essential for various industries, including oil and gas, construction, and water well drilling. These pipes are designed to fit specific project requirements, ensuring optimal performance and durability.

One of the first things to consider when looking for affordable customized casing pipe options is the material used. Casing pipes are typically made from materials such as steel, PVC, or fiberglass. Each material has its own set of advantages and disadvantages, so it’s important to choose the one that best suits your project needs while also keeping costs in mind.

Steel casing pipes are known for their strength and durability, making them a popular choice for demanding applications. However, steel pipes can be more expensive than other materials, so it’s important to shop around and compare prices from different suppliers. PVC casing pipes are a more affordable option and are often used in less demanding applications. Fiberglass casing pipes are lightweight and corrosion-resistant, making them a cost-effective choice for projects where weight and corrosion are concerns.

Another important factor to consider when looking for affordable customized casing pipe options is the size and length of the pipes. Customized casing pipes are available in a wide range of sizes and lengths to accommodate different project requirements. It’s important to accurately measure the dimensions needed for your project to avoid unnecessary costs associated with ordering pipes that are too large or too small.

In addition to material and size considerations, it’s also important to consider the manufacturing process used to create customized casing pipes. Some suppliers may offer lower prices by cutting corners on quality control or using inferior materials. It’s important to choose a reputable supplier that uses high-quality materials and follows strict manufacturing standards to ensure the pipes meet industry regulations and performance standards.

When comparing prices for customized casing pipes, it’s important to consider the total cost of the project, including shipping and installation costs. Some suppliers may offer lower prices on the pipes themselves but charge higher fees for shipping or installation services. It’s important to get a detailed quote that includes all costs associated with the project to avoid any surprises down the line.

Finally, it’s important to consider the reputation and customer reviews of the supplier when looking for affordable customized casing pipe options. A supplier with a strong track record of delivering high-quality products and excellent customer service is more likely to provide a reliable and cost-effective solution for your project.

In conclusion, finding affordable customized casing pipe options requires careful consideration of material, size, manufacturing process, total project costs, and supplier reputation. By taking the time to research and compare options, you can find a cost-effective solution that meets your project requirements without compromising on quality or performance.