Benefits of Using Oil Casting Pipes in Industrial Applications

Oil casting pipes are an essential component in various industrial applications, providing a reliable and efficient means of transporting oil and other fluids. These pipes are designed to withstand high temperatures and pressures, making them ideal for use in demanding environments. In this article, we will explore the details of oil casting pipes and how they work to benefit industrial processes.

Oil casting pipes are typically made from high-quality materials such as steel or iron, which are known for their strength and durability. These pipes are manufactured using a process known as casting, where molten metal is poured into a mold and allowed to cool and solidify. This method allows for the production of pipes with precise dimensions and smooth surfaces, ensuring optimal performance in industrial settings.

One of the key benefits of using oil casting pipes is their ability to withstand extreme conditions. These pipes are designed to handle high temperatures and pressures, making them suitable for use in oil refineries, chemical plants, and other industrial facilities where harsh operating conditions are common. The robust construction of oil casting pipes ensures that they can withstand the rigors of daily use without succumbing to wear and tear.

Another advantage of oil casting pipes is their resistance to corrosion. The materials used in the manufacturing of these pipes are chosen for their ability to resist rust and other forms of corrosion, ensuring a long service life and minimal maintenance requirements. This makes oil casting pipes a cost-effective solution for industrial applications, as they do not need to be replaced frequently due to deterioration.

oil pipe for sale in texasIn addition to their durability and corrosion resistance, oil casting pipes are also known for their versatility. These pipes can be customized to meet the specific requirements of different industrial processes, with options available for various sizes, shapes, and configurations. This flexibility allows for the seamless integration of oil casting pipes into existing systems, ensuring a smooth and efficient flow of fluids throughout the facility.

The design of oil casting pipes also plays a crucial role in their performance. These pipes are engineered to minimize friction and turbulence, allowing for the efficient transport of oil and other fluids with minimal energy loss. This results in improved efficiency and reduced operating costs, making oil casting pipes a preferred choice for industrial applications where energy conservation is a priority.

Overall, oil casting pipes offer a range of benefits for industrial applications, including durability, corrosion resistance, versatility, and efficiency. These pipes are essential for the safe and reliable transport of oil and other fluids in demanding environments, providing a cost-effective solution for industrial processes. With their robust construction and high performance, oil casting pipes are a valuable asset for any facility looking to optimize its operations and maximize productivity.

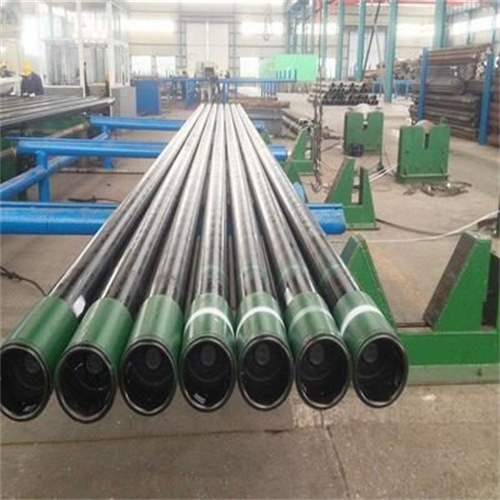

Step-by-Step Guide to the Oil Casting Pipe Manufacturing Process

Oil casting pipes are an essential component in the oil and gas industry, used to transport oil from the well to the refinery. These pipes are made using a process known as oil casting, which involves pouring molten metal into a mold to create the desired shape. In this article, we will take a closer look at the oil casting pipe manufacturing process and how it works.

The first step in the oil casting pipe manufacturing process is to create a mold of the desired pipe shape. This mold is typically made from sand, which is packed around a pattern of the pipe. The sand mold is then heated to a high temperature to harden it and create a cavity in the shape of the pipe.

Once the mold is ready, the next step is to prepare the metal for casting. The metal used for oil casting pipes is typically a high-strength alloy that can withstand the harsh conditions of the oil and gas industry. The metal is melted in a furnace to a precise temperature and then poured into the mold.

As the molten metal is poured into the mold, it fills the cavity created by the sand and takes on the shape of the pipe. The metal is left to cool and solidify, forming a solid pipe within the mold. Once the metal has cooled, the sand mold is broken away, revealing the newly cast oil casting pipe.

After the pipe has been removed from the mold, it undergoes a series of finishing processes to ensure it meets the required specifications. This may include machining the ends of the pipe to create a smooth surface for welding, as well as heat treating the pipe to improve its strength and durability.

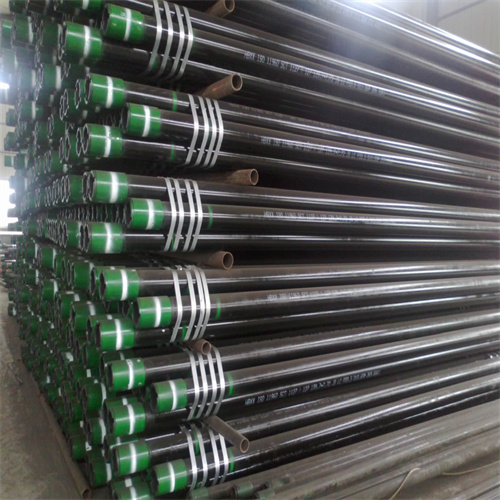

casing Pipe

Once the finishing processes are complete, the oil casting pipe is ready for inspection. The pipe is carefully examined for any defects or imperfections that could compromise its integrity. This may include using non-destructive testing methods such as ultrasonic testing to check for any internal flaws.

If the pipe passes inspection, it is then coated with a protective layer to prevent corrosion and ensure a long service life. This may involve applying a layer of epoxy or polyethylene to the surface of the pipe, which helps to protect it from the corrosive effects of the oil and gas it will be transporting.

In conclusion, oil casting pipes play a crucial role in the oil and gas industry, providing a reliable means of transporting oil from the well to the refinery. The manufacturing process for oil casting pipes involves creating a sand mold, melting the metal, pouring it into the mold, and finishing the pipe to meet the required specifications. By following these steps, manufacturers can produce high-quality oil casting pipes that meet the demanding requirements of the industry.