Understanding the Difference Between Oil casing and Drill Pipes

Oil casing and drill pipes are essential components in the oil and gas industry, playing a crucial role in the drilling and extraction process. While both serve important functions, there are distinct differences between the two that are important to understand. In this article, we will explore the differences between oil casing and drill pipes, shedding light on their unique characteristics and roles in the oil and gas industry.

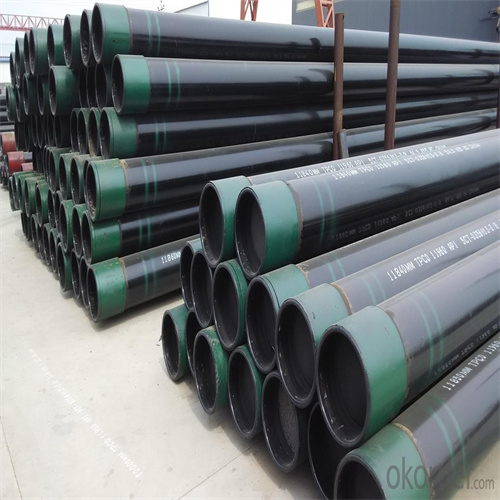

Oil casing is a large-diameter pipe that is installed in a wellbore to provide structural support and prevent the collapse of the well walls. It is typically made of steel and is designed to withstand high pressure and extreme conditions. Oil casing is used to line the wellbore and isolate the drilling fluid and the formation fluids, ensuring the integrity of the well and preventing contamination of the surrounding environment.

EVA Pouch

On the other hand, drill pipes are smaller-diameter pipes that are used to transmit drilling fluid and provide a conduit for the drilling bit to reach the desired depth. Drill pipes are connected to the drilling rig and are used to rotate the drilling bit and apply downward force to penetrate the rock formations. Unlike oil casing, drill pipes are not designed to provide structural support to the wellbore and are removed once the drilling process is complete.

oil transfer case typeOne of the key differences between oil casing and drill pipes is their size and design. Oil casing is typically larger and heavier than drill pipes, with thicker walls and a more robust construction. This is because oil casing needs to withstand the high pressure and weight of the overlying rock formations, while drill pipes are primarily used to transmit drilling fluid and provide a conduit for the drilling bit.

Another important difference between oil casing and drill pipes is their function in the drilling process. Oil casing is used to line the wellbore and provide structural support, while drill pipes are used to transmit drilling fluid and rotate the drilling bit. Oil casing is installed first in the wellbore, followed by the drill pipes, which are used to advance the drilling process and reach the desired depth.

Another important difference between oil casing and drill pipes is their function in the drilling process. Oil casing is used to line the wellbore and provide structural support, while drill pipes are used to transmit drilling fluid and rotate the drilling bit. Oil casing is installed first in the wellbore, followed by the drill pipes, which are used to advance the drilling process and reach the desired depth.

In terms of material composition, both oil casing and drill pipes are typically made of steel, but they may differ in terms of grade and specification. Oil casing is usually made of high-strength steel that can withstand high pressure and extreme conditions, while drill pipes are made of a more flexible and lightweight steel that allows for easier handling and manipulation during the drilling process.

In conclusion, oil casing and drill pipes are essential components in the oil and gas industry, each serving a unique function in the drilling and extraction process. While oil casing provides structural support and prevents the collapse of the wellbore, drill pipes transmit drilling fluid and rotate the drilling bit to reach the desired depth. Understanding the differences between oil casing and drill pipes is crucial for ensuring the success and safety of drilling operations in the oil and gas industry.