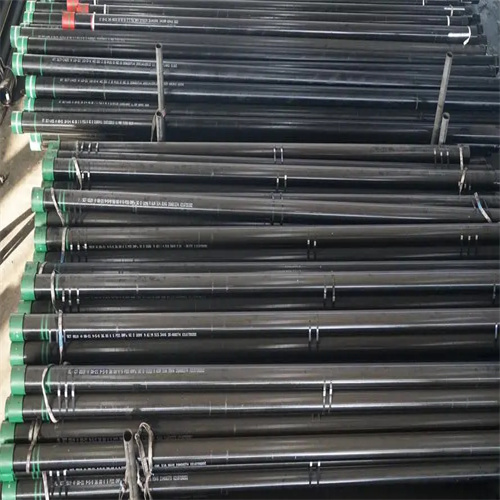

Benefits of Using API 5CT C90 casing Seamless steel Pipe in Oil and Gas Industry

API 5CT C90 casing seamless steel pipe is a popular choice in the oil and gas industry due to its numerous benefits. This type of pipe is known for its high strength, durability, and resistance to corrosion, making it ideal for use in demanding environments. In this article, we will explore the advantages of using API 5CT C90 casing seamless steel pipe in the oil and gas industry.

One of the key benefits of API 5CT C90 casing seamless steel pipe is its high strength. This type of pipe is made from high-quality steel that has been carefully engineered to withstand the extreme pressures and temperatures found in oil and gas wells. This means that API 5CT C90 casing seamless steel pipe is less likely to fail under stress, reducing the risk of costly downtime and repairs.

In addition to its high strength, API 5CT C90 casing seamless steel pipe is also highly durable. This type of pipe is designed to last for many years, even in harsh environments. Its resistance to corrosion and other forms of damage means that it can be relied upon to perform consistently over time, reducing the need for frequent replacements and repairs.

Another advantage of API 5CT C90 casing seamless steel pipe is its versatility. This type of pipe can be used in a wide range of applications, from drilling and production to transportation and storage. Its seamless design allows for easy installation and maintenance, while its high strength and durability make it suitable for use in a variety of conditions.

Furthermore, API 5CT C90 casing seamless steel pipe is also highly resistant to corrosion. This is a crucial factor in the oil and gas industry, where pipes are constantly exposed to corrosive substances such as saltwater, acids, and other chemicals. The corrosion-resistant properties of API 5CT C90 casing seamless steel pipe help to prolong its lifespan and ensure that it continues to perform effectively in challenging environments.

In conclusion, API 5CT C90 casing seamless steel pipe offers a range of benefits that make it an excellent choice for use in the oil and gas industry. Its high strength, durability, and resistance to corrosion make it a reliable and cost-effective option for a wide range of applications. Whether used in drilling, production, transportation, or storage, API 5CT C90 casing seamless steel pipe is sure to deliver exceptional performance and reliability.

How to Ensure Quality and Compliance When Using API 5CT C90 Casing Seamless Steel Pipe

API 5CT C90 casing seamless steel pipe is a popular choice in the oil and gas industry due to its high strength and durability. However, ensuring quality and compliance when using this type of pipe is crucial to prevent any potential safety hazards or operational issues. In this article, we will discuss some key factors to consider when using API 5CT C90 casing seamless steel pipe to ensure quality and compliance.

First and foremost, it is essential to source the API 5CT C90 casing seamless steel pipe from reputable and certified manufacturers. This ensures that the pipe meets the required industry standards and specifications, such as API 5CT and API 5L. Working with certified manufacturers also provides assurance that the pipe has undergone rigorous testing and quality control measures to ensure its integrity and performance.

When using API 5CT C90 casing seamless steel pipe, it is important to inspect the pipe for any defects or imperfections before installation. This includes checking for any cracks, dents, or corrosion that could compromise the structural integrity of the pipe. Additionally, it is crucial to verify that the pipe dimensions and wall thickness meet the specified requirements to ensure proper fit and functionality.

Proper handling and storage of API 5CT C90 casing seamless steel pipe are also critical to maintaining its quality and compliance. The pipe should be stored in a clean, dry, and well-ventilated area to prevent corrosion and contamination. It is important to handle the pipe with care to avoid any damage or deformation that could affect its performance during installation and operation.

sucked into an oil pipe

When installing API 5CT C90 casing seamless steel pipe, it is essential to follow the manufacturer’s recommended procedures and guidelines. This includes using the appropriate tools and equipment for cutting, threading, and welding the pipe to ensure a secure and leak-free connection. It is also important to inspect the pipe joints and connections for any signs of leakage or damage to prevent any potential safety hazards.

Regular maintenance and inspection of API 5CT C90 casing seamless steel pipe are crucial to ensure its continued performance and compliance with industry standards. This includes monitoring for any signs of wear, corrosion, or degradation that could affect the pipe’s integrity and functionality. It is important to address any issues promptly to prevent any potential safety risks or operational disruptions.

In conclusion, ensuring quality and compliance when using API 5CT C90 casing seamless steel pipe is essential to prevent any safety hazards or operational issues in the oil and gas industry. By sourcing the pipe from reputable manufacturers, inspecting for defects, proper handling and storage, following installation procedures, and conducting regular maintenance and inspection, you can ensure the integrity and performance of the pipe. By taking these steps, you can confidently use API 5CT C90 casing seamless steel pipe in your operations while meeting industry standards and regulations.

S355 Carbon Steel Pipe