The Importance of casing and Tubing in Oil and Gas Wells

Casing and tubing play a crucial role in the construction and operation of oil and gas wells. These components are essential for maintaining the integrity of the wellbore and ensuring the safe and efficient extraction of hydrocarbons from the reservoir. In this article, we will explore the importance of casing and tubing in oil and gas wells and discuss their key functions and characteristics.

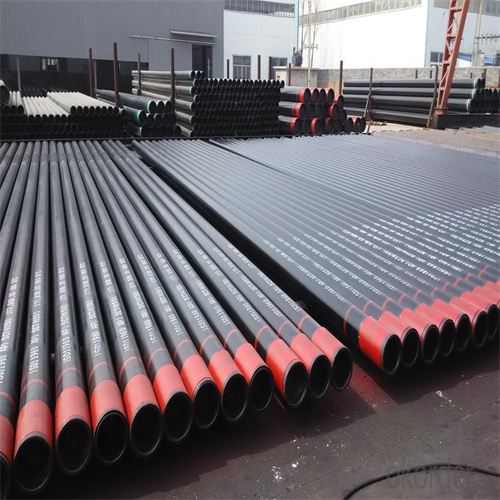

Casing is a large-diameter Pipe that is installed in the wellbore to provide structural support and prevent the collapse of the hole. It also serves as a barrier to prevent the migration of fluids between different geological formations. Casing is typically made of steel and is designed to withstand high pressures and temperatures. It is installed in sections, with each section being cemented in place to create a secure seal.

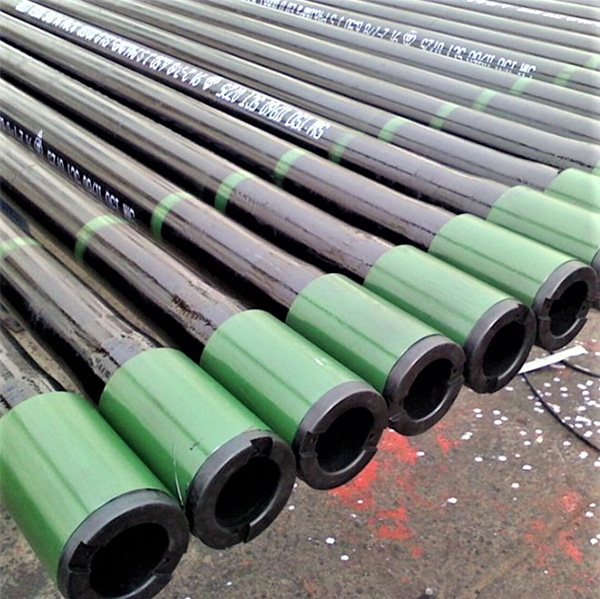

Tubing, on the other hand, is a smaller-diameter pipe that is inserted inside the casing to transport fluids from the reservoir to the surface. Tubing is also made of steel and is designed to withstand the corrosive effects of the produced fluids. It is connected to the surface equipment through a series of valves and fittings, allowing for the control and monitoring of the flow of fluids in the well.

oil rigs

One of the key functions of casing and tubing is to protect the wellbore from external forces and prevent the escape of fluids into the surrounding environment. Casing provides structural support to the wellbore and prevents it from collapsing under the weight of the overlying rock formations. It also isolates the different geological formations to prevent the mixing of fluids and the contamination of groundwater.

Tubing, on the other hand, provides a conduit for the flow of fluids from the reservoir to the surface. It is designed to withstand the corrosive effects of the produced fluids and to maintain the integrity of the wellbore. Tubing is also used to control the flow of fluids in the well and to facilitate the installation of downhole equipment such as pumps and sensors.

In addition to their structural and protective functions, casing and tubing also play a critical role in the production and completion of oil and gas wells. Casing is used during the drilling process to stabilize the wellbore and prevent it from collapsing. It is also used to isolate different geological formations and to provide a secure seal for the cement that is used to bond the casing to the surrounding rock.

In addition to their structural and protective functions, casing and tubing also play a critical role in the production and completion of oil and gas wells. Casing is used during the drilling process to stabilize the wellbore and prevent it from collapsing. It is also used to isolate different geological formations and to provide a secure seal for the cement that is used to bond the casing to the surrounding rock.

tubing beader tool,

Tubing, on the other hand, is used during the production phase to transport fluids from the reservoir to the surface. It is connected to the downhole pumps and other equipment that are used to extract the hydrocarbons from the well. Tubing is also used to inject fluids into the well for enhanced oil recovery and other production techniques.

In conclusion, casing and tubing are essential components of oil and gas wells that play a critical role in their construction and operation. These components provide structural support, protect the wellbore from external forces, and facilitate the production and completion of the well. By understanding the importance of casing and tubing, we can appreciate the complexity and sophistication of modern oil and gas drilling operations.