Understanding the Different Sizes of Oil Well casing

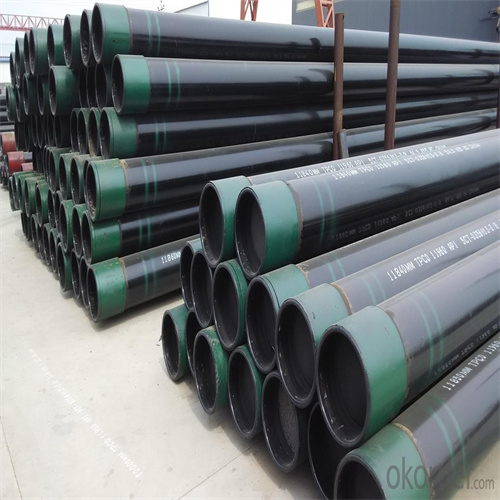

Oil well casing plays a crucial role in the drilling and production of oil and gas wells. It is a cylindrical Pipe that is inserted into the wellbore to protect and support the well and to prevent the surrounding soil or rock from collapsing into the well. Oil well casing comes in various sizes, each serving a specific purpose in the drilling and completion process.

The size of oil well casing is typically measured by its outside diameter, which is expressed in inches. The most common sizes of oil well casing range from 4 1/2 inches to 13 3/8 inches in diameter. The choice of casing size depends on several factors, including the depth of the well, the type of formation being drilled through, and the production requirements of the well.

The size of oil well casing is typically measured by its outside diameter, which is expressed in inches. The most common sizes of oil well casing range from 4 1/2 inches to 13 3/8 inches in diameter. The choice of casing size depends on several factors, including the depth of the well, the type of formation being drilled through, and the production requirements of the well.

oil sleeve bearingSmaller casing sizes, such as 4 1/2 inches and 5 inches, are commonly used in the initial stages of drilling a well. These smaller sizes are typically used to protect the wellbore from collapsing and to provide structural support during the drilling process. As the well is drilled deeper, larger casing sizes are often required to provide additional support and to prevent the wellbore from collapsing under the pressure of the surrounding rock formations.

Casing sizes of 7 inches and 9 5/8 inches are commonly used in intermediate stages of drilling, where the well is being drilled through multiple formations with varying pressures and geological characteristics. These larger casing sizes provide the necessary support and protection for the wellbore as it progresses deeper into the earth.

The largest casing sizes, such as 13 3/8 inches, are typically used in the final stages of drilling and completion, where the well is being prepared for production. These larger casing sizes are designed to withstand the high pressures and temperatures that are often encountered in deep wells and to provide a secure barrier between the wellbore and the surrounding formations.

In addition to the outside diameter, oil well casing is also classified by its weight per foot, which is a measure of the thickness and strength of the casing. The weight per foot of casing is typically expressed in pounds, with heavier casing sizes providing greater strength and durability for deep wells and challenging drilling conditions.

Radiator Hose

Transitional phrases such as “in addition to,” “as a result,” and “furthermore” can help guide the reader through the different sizes and classifications of oil well casing. By understanding the various sizes and classifications of oil well casing, drilling engineers and operators can make informed decisions about the type of casing to use in different stages of drilling and completion.

In conclusion, oil well casing comes in a range of sizes, from smaller diameters for initial drilling stages to larger diameters for deeper wells and production. The size and weight per foot of casing are important considerations in ensuring the structural integrity and safety of the wellbore. By choosing the right size and weight of casing for each stage of drilling and completion, operators can maximize the efficiency and productivity of their oil and gas wells.