Benefits of casing Pipe in Oil Well Drilling Operations

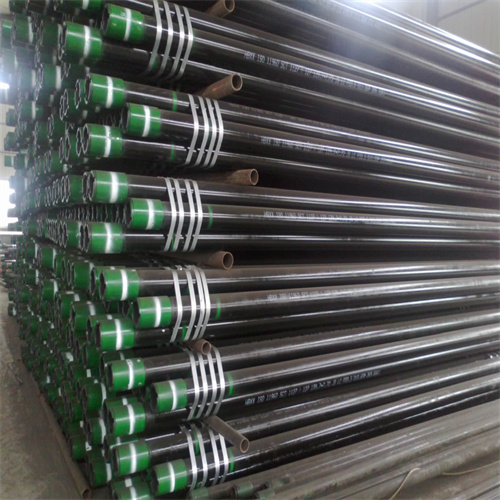

Casing pipes play a pivotal role in the success and safety of oil well drilling operations. These robust tubes are designed to line the walls of the drilled hole, providing structural integrity and preventing the collapse of the wellbore. Beyond mere support, casing pipes offer a plethora of benefits that are indispensable in the complex and demanding environment of oil exploration and production.

Firstly, casing pipes serve as a barrier between the wellbore and the surrounding geological formations. By isolating different layers of rock and sediment, they help to prevent the contamination of groundwater sources and minimize the risk of fluid migration between formations. This is particularly crucial in unconventional drilling methods such as hydraulic fracturing, where multiple layers of casing may be required to ensure the integrity of the well.

ASTMMoreover, casing pipes facilitate the efficient and safe extraction of hydrocarbons from the reservoir. By providing a conduit for the insertion of production Tubing and other downhole equipment, they enable the passage of fluids from the reservoir to the surface while maintaining control over pressure and flow rates. This is essential for maximizing production rates and optimizing the recovery of oil and gas reserves.

In addition to their functional advantages, casing pipes also offer economic benefits to oil companies. By protecting the integrity of the wellbore and prolonging the life of the well, they help to reduce the risk of costly downtime and remediation efforts. Furthermore, their use can result in significant savings in terms of time and resources during drilling operations, as they streamline the process of casing installation and cementing.

Another advantage of casing pipes is their versatility and adaptability to various drilling conditions and environments. They are available in a wide range of sizes, grades, and configurations to suit different well designs and geological formations. Whether drilling in shallow or deep formations, onshore or offshore, casing pipes can be customized to meet the specific requirements of each project, ensuring optimal performance and reliability.

Furthermore, advancements in materials and manufacturing technologies have enhanced the performance and durability of casing pipes, making them more resistant to corrosion, abrasion, and other forms of degradation. This not only extends the service life of the pipes but also reduces the need for costly maintenance and repairs over time.

In conclusion, casing pipes play a crucial role in oil well drilling operations, offering a multitude of benefits that contribute to the success, safety, and efficiency of the process. From providing structural support and isolation of formations to facilitating production and minimizing downtime, casing pipes are indispensable components of modern drilling practices. With continued innovation and advancements in technology, their importance is only expected to grow, ensuring the continued viability and sustainability of the oil and gas industry.

Key Considerations for Selecting the Right Casing Pipe for Oil Well Drilling

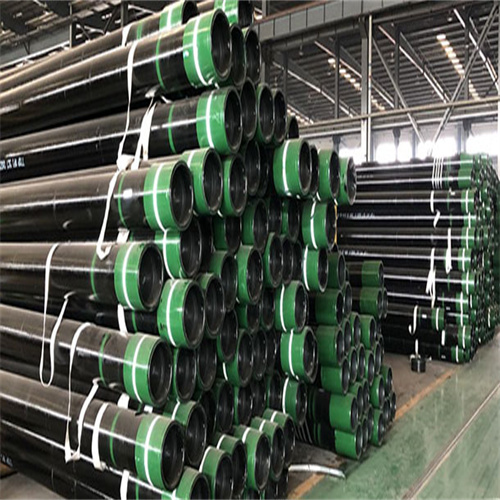

Casing pipes play a critical role in oil well drilling, providing structural integrity and protection to the wellbore. Selecting the right casing pipe is essential for ensuring the success and longevity of the drilling operation. Several key considerations must be taken into account when choosing the appropriate casing pipe for a specific drilling project.

One of the primary factors to consider is the depth and geology of the well. Deeper wells and challenging geological formations require casing pipes with higher tensile strength and resistance to corrosion and collapse. In such cases, steel casing pipes are often preferred due to their durability and ability to withstand high pressure and harsh environmental conditions.

One of the primary factors to consider is the depth and geology of the well. Deeper wells and challenging geological formations require casing pipes with higher tensile strength and resistance to corrosion and collapse. In such cases, steel casing pipes are often preferred due to their durability and ability to withstand high pressure and harsh environmental conditions.

Another crucial consideration is the diameter of the casing pipe. The diameter must be sufficient to accommodate the drilling equipment and allow for the installation of additional casing strings if needed. Additionally, the diameter of the casing pipe affects the flow rate of the produced fluids and the efficiency of the drilling process. Therefore, careful evaluation of the well’s specifications and production requirements is necessary to determine the appropriate casing diameter.

titanium gateway

In addition to the depth and diameter of the well, the type of reservoir and the anticipated downhole conditions also influence the selection of casing pipes. For instance, in reservoirs with high temperatures and corrosive fluids, corrosion-resistant casing materials such as stainless steel or corrosion-resistant alloys may be required to prevent premature degradation and failure of the casing.

Furthermore, considerations must be given to the cementing process, which involves filling the annular space between the casing and the wellbore wall with cement to provide zonal isolation and prevent fluid migration. The casing pipe must have suitable characteristics, such as proper centralization and cementing accessories, to ensure a successful cementing operation and a secure bond between the casing and the formation.

Another critical aspect to consider is the regulatory requirements and industry standards governing casing design and installation. Compliance with these standards is essential to ensure the safety and environmental sustainability of the drilling operation. Therefore, it is essential to work with reputable suppliers and manufacturers who adhere to industry best practices and provide casing pipes that meet the required specifications and certifications.

Furthermore, cost considerations play a significant role in the selection process. While it is important to choose high-quality casing pipes that meet the technical requirements of the drilling project, cost-effectiveness is also a key consideration. Therefore, evaluating the lifecycle cost of different casing options, including installation, maintenance, and operational expenses, is essential to make informed decisions and optimize the overall economics of the drilling operation.

In conclusion, selecting the right casing pipe for oil well drilling requires careful consideration of various factors, including the depth and geology of the well, casing diameter, downhole conditions, cementing requirements, regulatory compliance, and cost considerations. By thoroughly evaluating these factors and working with experienced professionals and reputable suppliers, drilling operators can ensure the success and efficiency of their drilling operations while minimizing risks and maximizing returns on investment.