Advantages and Disadvantages of steel Pipes in Oil Drilling

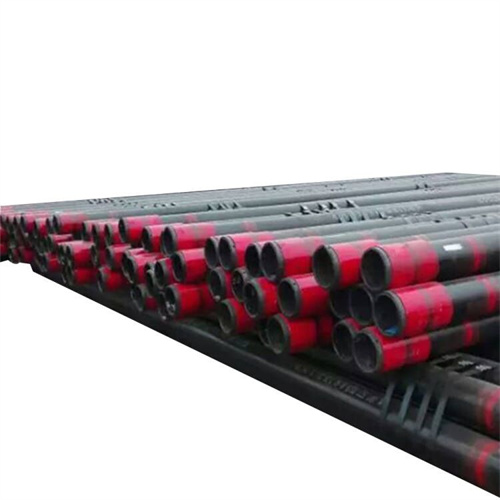

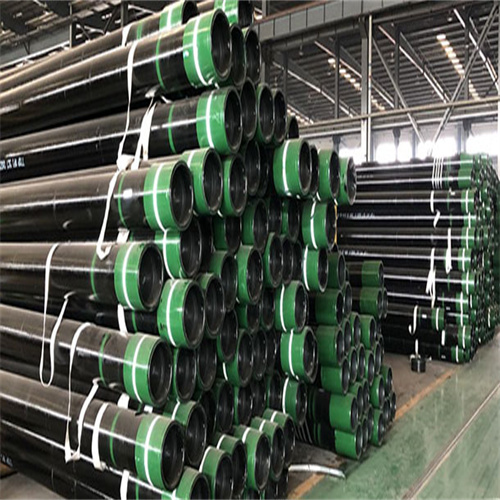

Oil drilling is a complex process that relies on various equipment and materials to extract crude oil from beneath the earth’s surface. One crucial component in this process is the type of pipe used for drilling. Among the options available, steel pipes are commonly employed due to their unique properties and suitability for the demanding conditions of oil drilling operations. However, like any material, steel pipes come with both advantages and disadvantages that must be carefully considered by oil drilling companies.

Steel pipes are favored in oil drilling for several reasons. Firstly, steel is known for its strength and durability, making it capable of withstanding the high pressures and harsh environments encountered during drilling operations. This strength ensures that steel pipes can effectively contain the oil and gas being extracted without succumbing to damage or failure. Additionally, steel pipes exhibit excellent resistance to corrosion, a critical factor given the corrosive nature of many substances found in oil wells. This corrosion resistance prolongs the lifespan of the pipes, reducing the need for frequent replacements and minimizing downtime in drilling operations.

Moreover, steel pipes offer versatility in terms of size, shape, and configuration, allowing them to be tailored to the specific requirements of each drilling project. This flexibility ensures that oil drilling companies can obtain pipes that meet their exact specifications, optimizing efficiency and performance on the rig. Furthermore, steel pipes are relatively easy to transport and install, simplifying logistics and reducing associated costs for oil drilling operations.

Despite these advantages, steel pipes also have certain drawbacks that must be taken into account. One notable disadvantage is their susceptibility to fatigue and stress corrosion cracking, especially in environments with high levels of hydrogen sulfide or other corrosive elements. This can compromise the integrity of the pipes over time, leading to leaks or failures that pose safety risks and can result in costly repairs or remediation efforts.

Additionally, steel pipes are relatively heavy compared to alternative materials such as plastic or composite pipes. This weight can make handling and installation more challenging, requiring specialized equipment and personnel to maneuver the pipes into position safely. Furthermore, steel is a finite resource, and the production of steel pipes involves energy-intensive processes that contribute to carbon emissions and environmental impact.

Additionally, steel pipes are relatively heavy compared to alternative materials such as plastic or composite pipes. This weight can make handling and installation more challenging, requiring specialized equipment and personnel to maneuver the pipes into position safely. Furthermore, steel is a finite resource, and the production of steel pipes involves energy-intensive processes that contribute to carbon emissions and environmental impact.

Despite these drawbacks, the advantages of steel pipes often outweigh the disadvantages in the context of oil drilling operations. Their strength, durability, and resistance to corrosion make them well-suited for the demanding conditions encountered in oil wells. However, ongoing research and development efforts are focused on addressing the limitations of steel pipes and exploring alternative materials that offer improved performance and sustainability.

In conclusion, steel pipes play a vital role in oil drilling operations, offering numerous advantages such as strength, durability, and corrosion resistance. However, they also have drawbacks, including susceptibility to fatigue and environmental concerns associated with their production. By carefully weighing these factors, oil drilling companies can make informed decisions regarding the use of steel pipes and explore opportunities for innovation and improvement in the field of oil drilling technology.

Exploring the Role of PVC Pipes in Oil Drilling Operations

Oil drilling operations rely on a complex network of equipment and materials to extract crude oil from the earth’s surface. Among these essential components are pipes, which play a crucial role in the extraction process. When it comes to choosing the right pipe for oil drilling, several factors come into play. One of the commonly used types of pipe in oil drilling operations is PVC pipe.

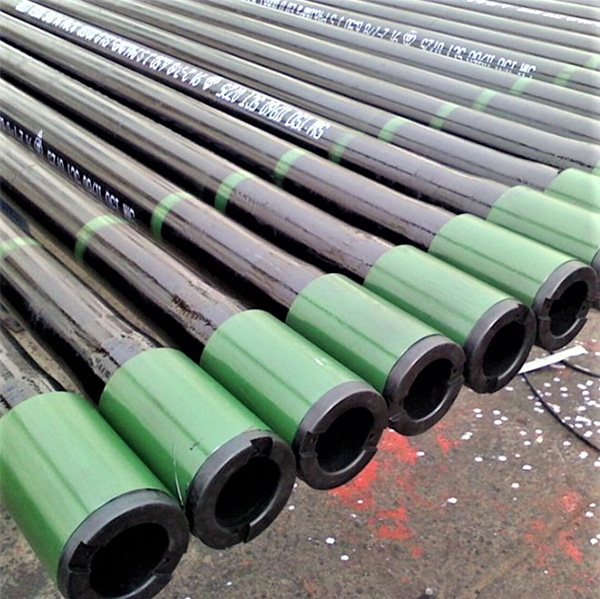

PVC, or polyvinyl chloride, is a versatile and durable material known for its strength and chemical resistance. These properties make PVC pipes well-suited for various industrial applications, including oil drilling. In oil drilling operations, PVC pipes are primarily used for casing and Tubing purposes.

Casing pipes are essential for maintaining the structural integrity of the wellbore and protecting the surrounding environment from contamination. PVC casing pipes offer several advantages in oil drilling applications. Firstly, PVC pipes are lightweight, making them easier to handle and install compared to traditional metal pipes. This characteristic reduces labor costs and simplifies logistics during drilling operations.

Furthermore, PVC pipes are resistant to corrosion, which is particularly advantageous in environments where exposure to corrosive substances such as saltwater is common. Corrosion-resistant PVC pipes help extend the lifespan of oil wells, reducing maintenance requirements and operational downtime.

Another critical application of PVC pipes in oil drilling is tubing. Tubing pipes are used to transport oil and gas from the reservoir to the surface. PVC tubing pipes are preferred for certain oil drilling operations due to their chemical resistance and smooth surface finish. The smooth interior surface of PVC pipes minimizes friction, allowing for efficient fluid flow and reducing the risk of blockages.

Moreover, PVC pipes offer excellent thermal insulation properties, helping to maintain the temperature of the transported fluids during extraction. This feature is particularly beneficial in extreme environmental conditions, where temperature fluctuations can impact the efficiency of oil drilling operations.

In addition to their functional benefits, PVC pipes are also cost-effective compared to alternative materials such as steel or aluminum. The lower cost of PVC pipes makes them an attractive option for oil drilling companies looking to optimize their operational expenses without compromising on performance.

Despite their many advantages, PVC pipes may not be suitable for all oil drilling applications. In high-pressure or high-temperature environments, PVC pipes may not possess the necessary strength to withstand the extreme conditions. In such cases, oil drilling companies may opt for alternative materials such as steel or composite pipes.

Furthermore, environmental considerations must be taken into account when using PVC pipes in oil drilling operations. While PVC is known for its chemical resistance, certain additives used in its production process may raise concerns about environmental impact. Proper disposal and recycling practices are essential to minimize the environmental footprint of PVC pipes in oil drilling activities.

durchlassrohr

oil tube chinese high-quality wholesalerIn conclusion, PVC pipes play a significant role in oil drilling operations, particularly in casing and tubing applications. Their lightweight, corrosion-resistant, and cost-effective nature make them a preferred choice for many oil drilling companies. However, the suitability of PVC pipes depends on the specific requirements of each drilling project and environmental considerations. By carefully evaluating the advantages and limitations of PVC pipes, oil drilling companies can make informed decisions to optimize their operations while minimizing environmental impact.