Identifying Key Differences Between Oil casing Pipe and Oil Drill Pipe

Oil casing pipe and oil drill pipe are both essential components in the oil and gas industry, but they serve distinct purposes and have specific characteristics that differentiate them. Understanding these differences is crucial for professionals working in the field, as it ensures the proper selection and utilization of these pipes in various applications.

iPhone 5 5s Se Covers casesFirstly, let’s delve into the basic functions of each type of pipe. Oil casing pipe is primarily used to line the walls of a borehole during the drilling process. It provides structural support to the wellbore and prevents it from collapsing. Additionally, casing pipes also isolate different geological formations to prevent fluid migration between them, thus maintaining the integrity of the well.

On the other hand, oil drill pipe is designed specifically for drilling operations. It is used to transmit drilling mud from the surface to the drill bit at the bottom of the wellbore. This mud serves multiple purposes, including cooling the drill bit, carrying drill cuttings to the surface, and maintaining pressure in the wellbore to prevent blowouts.

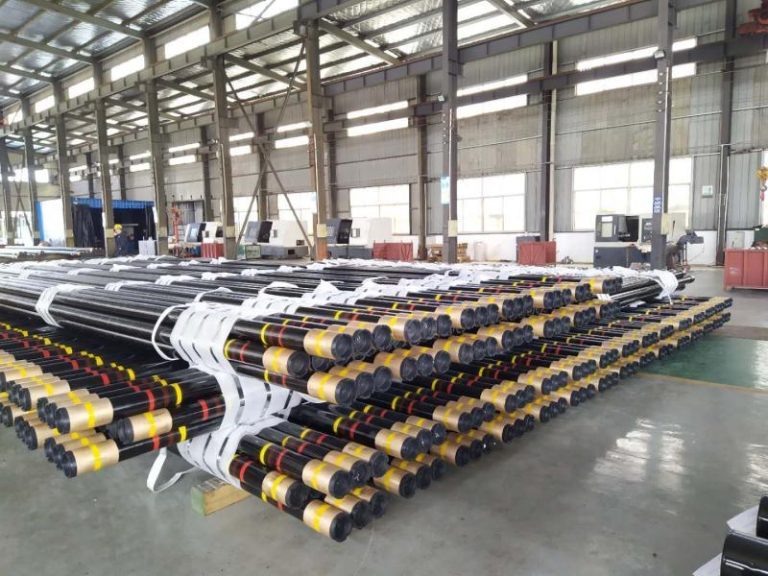

One of the key differences between oil casing pipe and oil drill pipe lies in their construction and material composition. Oil casing pipes are typically larger and thicker than drill pipes to withstand the external pressure exerted by the surrounding geological formations. They are often made of high-strength carbon or alloy steel to ensure durability and resistance to corrosion.

In contrast, oil drill pipes are designed to be more lightweight and flexible to facilitate the drilling process. They are usually made of high-strength steel alloys to withstand the internal pressure of the drilling mud while being able to endure the bending and torsional forces exerted during drilling operations.

Another distinguishing feature between oil casing pipe and oil drill pipe is their threading configuration. Casing pipes are typically threaded at both ends to allow for easy connection and installation in the wellbore. These threads are usually tapered to provide a tight seal and prevent leaks.

In contrast, drill pipes feature a more complex threading configuration known as tool joints. These tool joints are thicker and stronger than the rest of the pipe to withstand the stresses encountered during drilling. They also incorporate special threads that are designed to withstand the high torque and tension experienced during drilling operations.

Furthermore, the lengths of oil casing pipe and oil drill pipe differ based on their respective functions. Casing pipes are typically longer and come in standardized lengths to accommodate the depth of the wellbore. In contrast, drill pipes are shorter and are connected together in sections called stands to reach the desired drilling depth.

In summary, oil casing pipe and oil drill pipe serve distinct purposes in the oil and gas industry and possess specific characteristics that differentiate them. Understanding these differences is essential for professionals involved in drilling operations to ensure the proper selection and utilization of these critical components. From their construction and material composition to their threading configuration and lengths, each type of pipe plays a vital role in the success of drilling projects.

A Comprehensive Guide to Distinguishing Oil Casing Pipe from Oil Drill Pipe

In the world of oil extraction, understanding the various components and equipment involved is crucial for professionals in the field. Two fundamental components in this industry are oil casing pipes and oil drill pipes. While they may seem similar at first glance, they serve distinct purposes in the drilling process. Differentiating between them is essential for ensuring efficient and safe operations. In this comprehensive guide, we will delve into the key characteristics of oil casing pipes and oil drill pipes, highlighting their differences and the importance of distinguishing between the two.

oil housing 1.8t

Oil casing pipes and oil drill pipes are integral parts of the oil drilling process, each serving a unique function. Oil casing pipes are primarily used to line the walls of a drilled well, providing structural support and preventing collapse. They also serve to isolate the oil and natural gas produced during drilling, preventing contamination of surrounding soil and water sources. In contrast, oil drill pipes are used to transmit drilling fluid to the drill bit and facilitate the drilling process. These pipes are subject to high levels of stress and must withstand extreme pressure and torque.

One of the primary differences between oil casing pipes and oil drill pipes lies in their design and construction. Oil casing pipes are typically thicker and heavier than drill pipes, with reinforced walls to withstand the immense pressure exerted by the surrounding rock formations. They are often made of high-strength steel alloys to ensure durability and longevity in harsh drilling environments. In contrast, oil drill pipes are designed to be lightweight and flexible, allowing for easy handling and maneuverability during the drilling process. They are often constructed from specialized steel alloys that offer a balance of strength and flexibility.

Another key distinction between oil casing pipes and oil drill pipes is their usage within the wellbore. Oil casing pipes are installed once drilling is complete, serving as a permanent fixture within the well to support the surrounding rock formations and maintain the integrity of the wellbore. They are typically cemented in place to further reinforce the structure and prevent fluid migration. On the other hand, oil drill pipes are used temporarily during the drilling process and are removed once the desired depth is reached. They are repeatedly inserted and removed from the wellbore as drilling progresses, making them essential for the overall efficiency and success of the operation.

Another key distinction between oil casing pipes and oil drill pipes is their usage within the wellbore. Oil casing pipes are installed once drilling is complete, serving as a permanent fixture within the well to support the surrounding rock formations and maintain the integrity of the wellbore. They are typically cemented in place to further reinforce the structure and prevent fluid migration. On the other hand, oil drill pipes are used temporarily during the drilling process and are removed once the desired depth is reached. They are repeatedly inserted and removed from the wellbore as drilling progresses, making them essential for the overall efficiency and success of the operation.

It is also important to consider the dimensions and specifications of oil casing pipes and oil drill pipes when distinguishing between the two. Oil casing pipes are available in a range of sizes and lengths to accommodate different well designs and drilling requirements. They are often characterized by their larger diameter and thicker walls compared to drill pipes. In contrast, oil drill pipes are standardized in size and typically feature a uniform diameter and wall thickness to ensure compatibility with drilling equipment and accessories.

In conclusion, while oil casing pipes and oil drill pipes may share some similarities, they serve distinct functions within the oil drilling process. Understanding the differences between these two components is essential for ensuring the safety, efficiency, and success of drilling operations. By considering factors such as design, construction, usage, and dimensions, professionals in the oil and gas industry can effectively differentiate between oil casing pipes and oil drill pipes, ultimately contributing to the overall success of oil exploration and extraction endeavors.