The Importance of casing in Oil and Gas Well Drilling

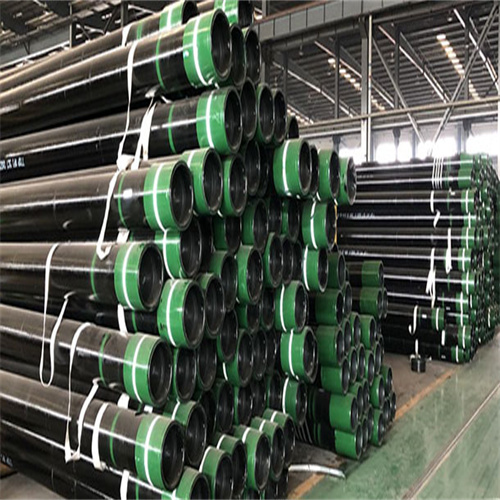

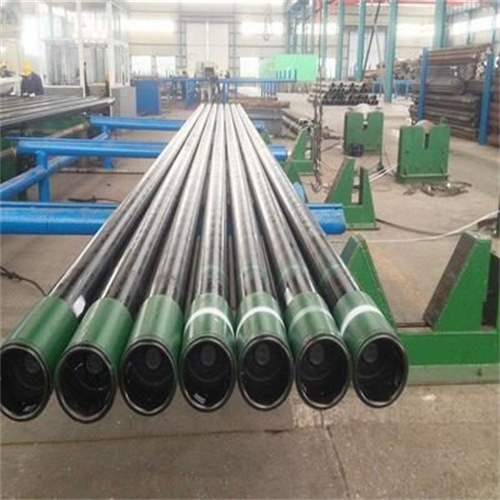

Oil and gas well drilling is a complex process that involves various stages to extract these valuable resources from the earth’s subsurface. Among these stages, casing plays a crucial role in ensuring the integrity and efficiency of the well. Casing refers to the steel Pipe sections inserted into the drilled hole to prevent it from collapsing and to isolate different geological formations. In this article, we will delve into the importance of casing in oil and gas well drilling, highlighting its functions and significance in maintaining well integrity and safety.

Firstly, casing serves as a structural support system for the wellbore. As drilling progresses deeper into the earth, the surrounding rock formations exert immense pressure on the borehole walls. Without adequate support, the hole could collapse, jeopardizing the entire drilling operation. Casing prevents this collapse by providing a sturdy barrier that reinforces the walls of the wellbore, ensuring its stability throughout the drilling process.

transmission oil changeMoreover, casing plays a crucial role in preventing fluid migration between different geological formations. During drilling, various fluids, including oil, gas, and water, are encountered within the subsurface layers. Without proper isolation, these fluids can intermingle, leading to contamination and potential environmental hazards. Casing acts as a barrier, preventing the migration of fluids between formations and ensuring that each zone remains isolated and intact.

Additionally, casing facilitates the implementation of well control measures, particularly during drilling and completion operations. In the event of unexpected pressure surges or blowouts, casing provides a containment barrier, allowing operators to regain control of the well and prevent hazardous incidents. By isolating problematic zones and providing a barrier against pressure build-up, casing enhances the safety and efficiency of drilling operations, minimizing risks to personnel and the environment.

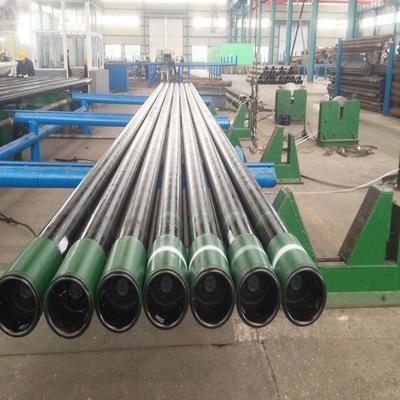

Furthermore, casing serves as a conduit for various downhole tools and equipment used during drilling and completion operations. By providing a stable and secure channel, casing enables the deployment of tools such as production Tubing, packers, and downhole sensors, essential for well evaluation, production optimization, and reservoir management. This versatility enhances the functionality of the well, allowing for efficient operations and enhanced productivity.

In addition to its structural and operational benefits, casing also plays a vital role in well completion and production. Once drilling is complete, casing facilitates the installation of cement sheaths between the wellbore and the surrounding formation. These cement barriers provide additional support and sealing, preventing fluid migration and ensuring long-term integrity. Furthermore, casing serves as a conduit for production tubing, allowing for the extraction of oil and gas from the reservoir to the surface.

In conclusion, casing is an indispensable component of oil and gas well drilling, serving multiple functions that are essential for the integrity, safety, and efficiency of the operation. From providing structural support and isolation to facilitating well control and production, casing plays a pivotal role at every stage of the drilling process. As the oil and gas industry continues to evolve, the importance of casing in ensuring the success and sustainability of drilling operations cannot be overstated.

Common Challenges Faced in Drilling Oil and Gas Wells

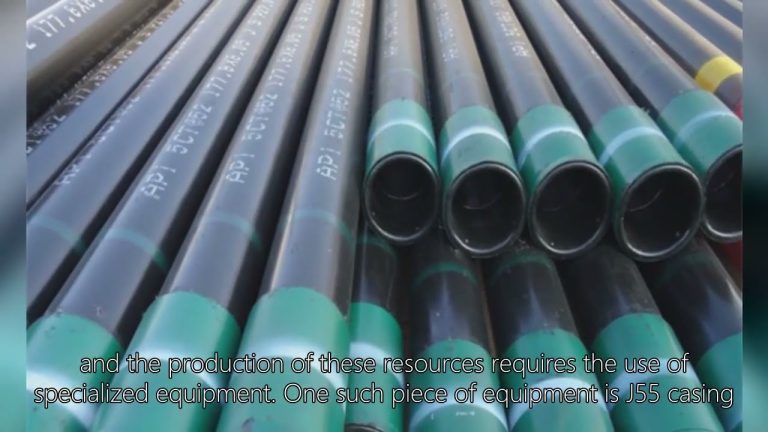

Oil and gas well drilling and servicing is a complex and crucial process in the extraction of petroleum and natural gas from the Earth’s subsurface. Within this intricate operation, drilling plays a pivotal role, serving as the initial phase in the journey of extracting these valuable resources. Among the myriad of tasks involved in drilling, casing, the process of installing steel pipe into the wellbore, stands out as a critical step. However, like any industrial endeavor, drilling and casing present numerous challenges that must be navigated adeptly to ensure efficiency, safety, and success.

One of the primary challenges encountered in drilling oil and gas wells is geological complexity. Each drilling site presents a unique geological makeup, characterized by variations in rock formations, pressures, and fluid content. Navigating through these heterogeneous formations demands meticulous planning and precise execution to prevent complications such as stuck pipe, lost circulation, or wellbore instability. Engineers and geologists rely on advanced technology, including seismic imaging and well logging, to gather comprehensive data and formulate effective drilling strategies tailored to the specific geological conditions.

Oil Well PipeIn addition to geological complexity, drilling operations often encounter challenges related to equipment reliability and performance. The harsh environment of drilling rigs, with exposure to extreme temperatures, high pressures, and abrasive drilling fluids, puts considerable strain on drilling equipment. Mechanical failures or malfunctions can disrupt operations, leading to costly downtime and delays. To mitigate these risks, operators invest in robust equipment maintenance programs and employ advanced monitoring systems to detect potential issues early and implement timely interventions.

Furthermore, environmental considerations pose significant challenges in drilling operations, particularly in sensitive ecosystems or densely populated areas. Minimizing the environmental footprint of drilling activities requires adherence to stringent regulations and the implementation of best practices for waste management, water conservation, and emissions control. innovations in drilling technologies, such as closed-loop drilling systems and eco-friendly drilling fluids, aim to reduce environmental impact while maintaining operational efficiency.

Furthermore, environmental considerations pose significant challenges in drilling operations, particularly in sensitive ecosystems or densely populated areas. Minimizing the environmental footprint of drilling activities requires adherence to stringent regulations and the implementation of best practices for waste management, water conservation, and emissions control. innovations in drilling technologies, such as closed-loop drilling systems and eco-friendly drilling fluids, aim to reduce environmental impact while maintaining operational efficiency.

Safety remains paramount in the oil and gas industry, and drilling operations are inherently hazardous due to the presence of heavy machinery, high-pressure fluids, and flammable gases. Preventing accidents and ensuring the well-being of workers necessitates rigorous safety protocols, comprehensive training, and constant vigilance. From well control procedures to personal protective equipment, every aspect of drilling operations must prioritize safety to mitigate the risk of incidents that could have catastrophic consequences.

Moreover, logistical challenges often arise in drilling projects, especially in remote or offshore locations with limited access to infrastructure and support services. Transporting equipment and personnel to and from the drilling site, managing supply chains, and coordinating activities across multiple stakeholders demand meticulous planning and coordination. Advanced logistics management systems and strategic partnerships with logistics providers help streamline operations and optimize resource allocation, reducing costs and enhancing efficiency.

Despite these challenges, advancements in technology and operational practices continue to drive improvements in drilling efficiency, safety, and environmental performance. From automated drilling systems and real-time data analytics to sustainable drilling techniques, the industry is constantly innovating to overcome challenges and maximize the yield of oil and gas reserves.

In conclusion, drilling oil and gas wells, particularly the casing process, presents a myriad of challenges that require expertise, innovation, and meticulous planning to overcome. From geological complexity and equipment reliability to environmental considerations and safety concerns, addressing these challenges is essential to ensure the success and sustainability of drilling operations. By embracing technological advancements, adhering to best practices, and prioritizing safety and environmental stewardship, the oil and gas industry can navigate these challenges effectively and continue to meet the world’s energy needs responsibly.