Understanding the Importance of casing in Oil Well Construction

Oil well construction is a complex process that involves several crucial steps to ensure the successful extraction of oil and gas from underground reservoirs. Among these steps, casing and Tubing play a pivotal role in maintaining the integrity of the well and safeguarding the surrounding environment. Understanding the importance of casing in oil well construction is essential for industry professionals and stakeholders alike.

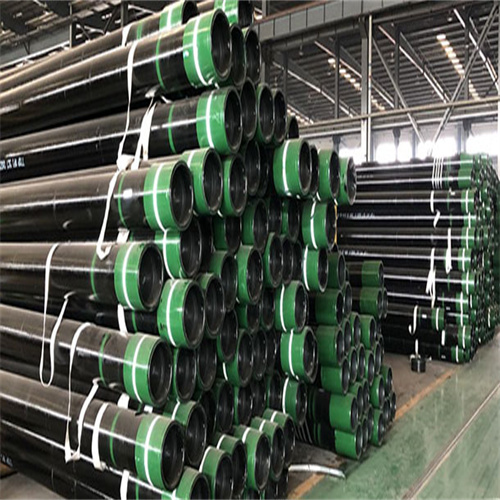

Casing serves as a protective barrier that lines the inside of the wellbore, preventing the collapse of the surrounding formations and the contamination of groundwater sources. It also provides structural support to the well, allowing for the efficient and safe extraction of hydrocarbons from deep beneath the Earth’s surface. Without proper casing, the integrity of the well could be compromised, leading to costly and potentially catastrophic consequences.

One of the primary functions of casing is to isolate different geological formations encountered during drilling. As the wellbore penetrates various rock layers, each with its own unique characteristics and pressures, the casing helps prevent fluid migration between these formations. This is crucial for maintaining well control and preventing blowouts, which can have devastating environmental and safety implications.

In addition to isolating formations, casing also serves as a conduit for the production of oil and gas to the surface. Once the drilling process is complete, production casing is installed and cemented in place to create a permanent seal. This ensures that hydrocarbons flow smoothly from the reservoir to the surface, where they can be processed and transported for further refinement.

Furthermore, casing provides protection against external forces such as pressure and corrosion. Deep within the Earth, wells are subjected to immense pressures from the surrounding rock formations. Casing helps contain these pressures, preventing the wellbore from collapsing or rupturing. Additionally, casing materials are selected for their resistance to corrosion, ensuring the long-term integrity of the well in harsh environments.

In oil well construction, selecting the appropriate casing design and materials is critical for ensuring the success and longevity of the well. Factors such as depth, formation characteristics, and anticipated production rates must be carefully considered to determine the optimal casing specifications. Engineers rely on advanced modeling techniques and industry best practices to make informed decisions and mitigate risks associated with casing failure.

Once casing is installed, tubing is inserted into the well to facilitate the production of oil and gas. Tubing serves as a conduit through which hydrocarbons flow from the reservoir to the surface, where they are collected and processed. Like casing, tubing must be carefully selected to withstand the corrosive effects of production fluids and operating conditions.

In conclusion, casing and tubing play indispensable roles in oil well construction, providing structural support, fluid isolation, and environmental protection. Understanding the importance of casing is essential for ensuring the safety, efficiency, and sustainability of oil and gas operations. By adhering to best practices and employing state-of-the-art technologies, industry professionals can effectively mitigate risks and optimize the performance of oil wells around the world.

Exploring the Role of Tubing in Efficient Oil Well Operations

Oil well construction is a complex process that requires meticulous planning and execution to ensure the efficient extraction of oil and gas resources from beneath the earth’s surface. Among the crucial components of oil well construction are casing and tubing, which play integral roles in maintaining the structural integrity of the well and facilitating the flow of hydrocarbons to the surface.

oil housing unit jeepCasing serves as the primary structural component of an oil well, providing support and protection to the wellbore against external pressures and preventing the collapse of the formation. Typically made of steel, casing is installed during the initial phases of drilling and is cemented into place to create a secure barrier between the wellbore and surrounding rock formations. This process not only stabilizes the well but also helps prevent fluid migration and maintains wellbore integrity.

Once the casing is installed, tubing is then inserted into the wellbore to facilitate the production of oil and gas. Tubing, also constructed from steel, serves as a conduit through which hydrocarbons flow from the reservoir to the surface. Unlike casing, which is set in place permanently, tubing can be retrieved and replaced as needed, allowing for more flexibility in well operations.

One of the key functions of tubing is to protect the casing and formation from the corrosive effects of produced fluids and gases. Over time, exposure to these corrosive elements can degrade the integrity of the casing, leading to costly repairs and potentially jeopardizing the safety of the well. By providing a barrier between the casing and the produced fluids, tubing helps extend the lifespan of the well and ensures continued production efficiency.

Additionally, tubing plays a crucial role in controlling the flow of fluids within the wellbore. Through the use of pumps and other artificial lift mechanisms, operators can regulate the rate at which oil and gas are produced, maximizing recovery while minimizing the risk of reservoir damage. Tubing also allows for the injection of fluids into the wellbore for enhanced oil recovery techniques such as water or gas injection, further optimizing production rates and ultimate resource recovery.

Carbon Seamless Steel PipeFurthermore, tubing facilitates the installation of downhole equipment such as pumps, packers, and sensors, which are essential for monitoring and optimizing well performance. These tools enable operators to gather valuable data on reservoir dynamics, production rates, and wellbore conditions, allowing for informed decision-making and proactive maintenance strategies.

In conclusion, tubing plays a vital role in the efficient operation of oil wells by providing structural support, facilitating fluid flow, and protecting the integrity of the wellbore. Together with casing, tubing forms the foundation of oil well construction, ensuring the safe and sustainable extraction of hydrocarbon resources. By understanding the importance of tubing in well operations, operators can optimize production rates, minimize downtime, and maximize the economic potential of oil and gas reservoirs.